Applicable Industries:

Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Restaurant, Printing Shops, Construction Works , Energy & Mining, Advertising Company

Showroom Location:

United States, Mexico, Russia, Argentina, Colombia, South Africa, Kazakhstan, Ukraine, Japan

Condition:

New

Machine Type:

Glass Washing And Drying Machine

Production Capacity:

300-500 Pc

Voltage:

3P/380V/60HZ

Power:

85KW

Dimension(L*W*H):

9000*3500*2400mm

Weight:

4000kg

Warranty:

1 Year

Key Selling Points:

Easy To Operate

Glass Thickness:

1-40mm

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Marketing Type:

New Product 2020

Warranty Of Core Components:

2 Years

Core Components:

Pressure Vessel, Motor, Bearing, Gear, PLC, Pump, Engine, Gearbox

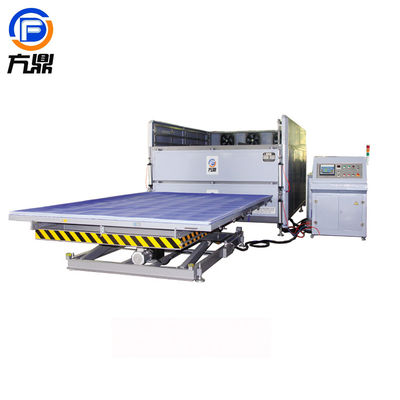

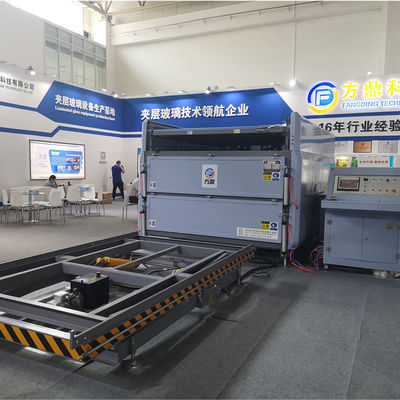

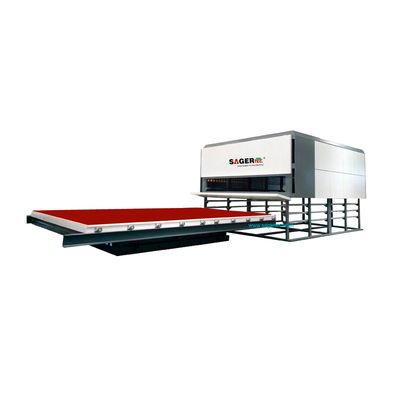

Product Name:

Pvb Automated Laminated Glass Machine

Max.glass::

3600*1800mm

Min.glass::

100*100mm

Weight::

4000kg

Overall Dimension:

9000*3500*2400mm

Input Power::

3P/380V/60HZ

Total Power::

85KW

Capacity(SQ.M/8H):

300

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

France, Brazil, Mexico, Russia, Japan, Malaysia, South Korea, Chile, Sri Lanka

Certification:

Ce

After-sales Service Provided:

Online Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!