Applicable Industries:

Building Material Shops, Manufacturing Plant, Construction WorksÂ

Showroom Location:

None

Condition:

New

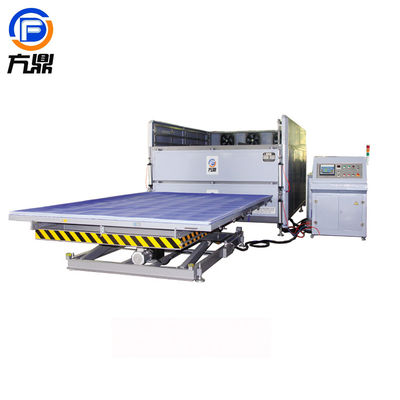

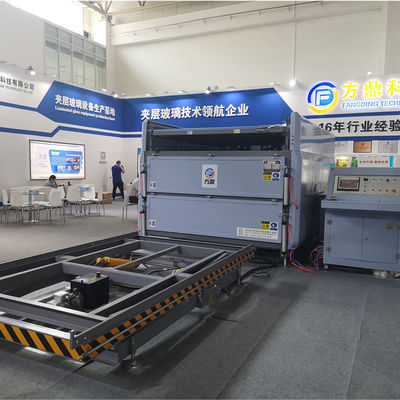

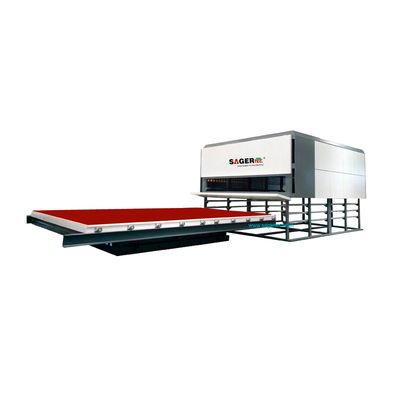

Machine Type:

Glass Tempering Furnace

Production Capacity:

5mm 16-18 Load/h

Power:

50-1500KW

Weight:

35000 Kg

Warranty:

1 Year

Key Selling Points:

Efficient

Glass Thickness:

4-19mm

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Marketing Type:

New Product 2020

Warranty Of Core Components:

1 Year

Core Components:

Motor, Gear, PLC, Gearbox

Voltage:

Custom Made

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, Turkey, United Kingdom, Germany, Viet Nam, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangl

Certification:

Ce

After-sales Service Provided:

Online Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!