Applicable Industries:

Hotels, Manufacturing Plant, Machinery Repair Shops, Restaurant, Home Use, Construction WorksÂ

Showroom Location:

None

Condition:

New

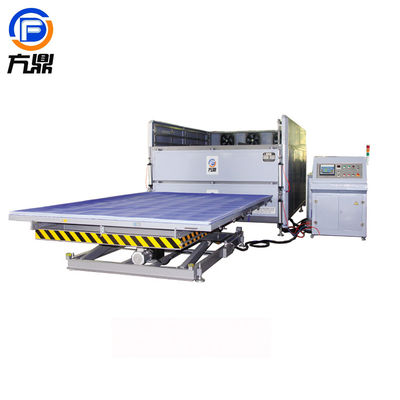

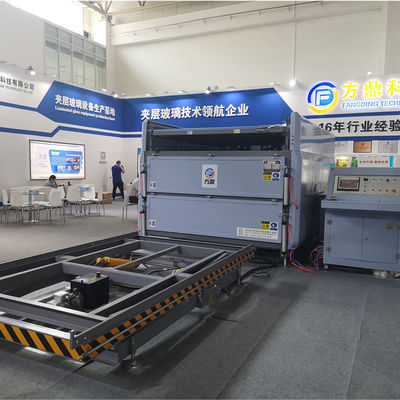

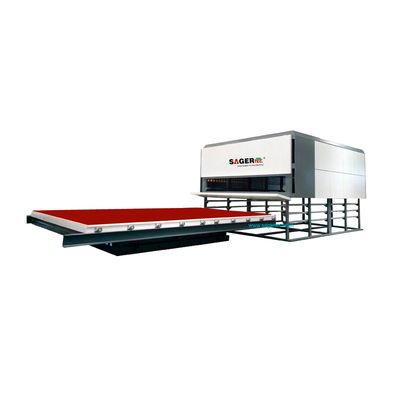

Machine Type:

Glass Tempering Furnace

Production Capacity:

98%

Voltage:

380V

Power:

630KW

Dimension(L*W*H):

21317*5890*3000mm

Weight:

36000KGS

Warranty:

1 Year

Key Selling Points:

Automatic

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

None

Certification:

Ce

After-sales Service Provided:

Online Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support

Application:

Architecture, Furniture, Household Appliance, Shower Room

Glass Thickness:

4-19mm

Glass Can Be Tempered:

Low-E Glass,clear Glass,tinted Glass,pattern ,screen Printed Glass

Installed Power:

630KVA

Heating Method:

Radiation+Convection

Min. Glass Size:

150*300mm

Max Flat Glass Size:

2440*3660mm

Max. Bending Size:

2440*1500mm

World Famous Parts:

Vesuvius Rollers, Siemens PLC, Siemens Inverter

Product Keywords:

Curve Glass Tempering Machinery

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!